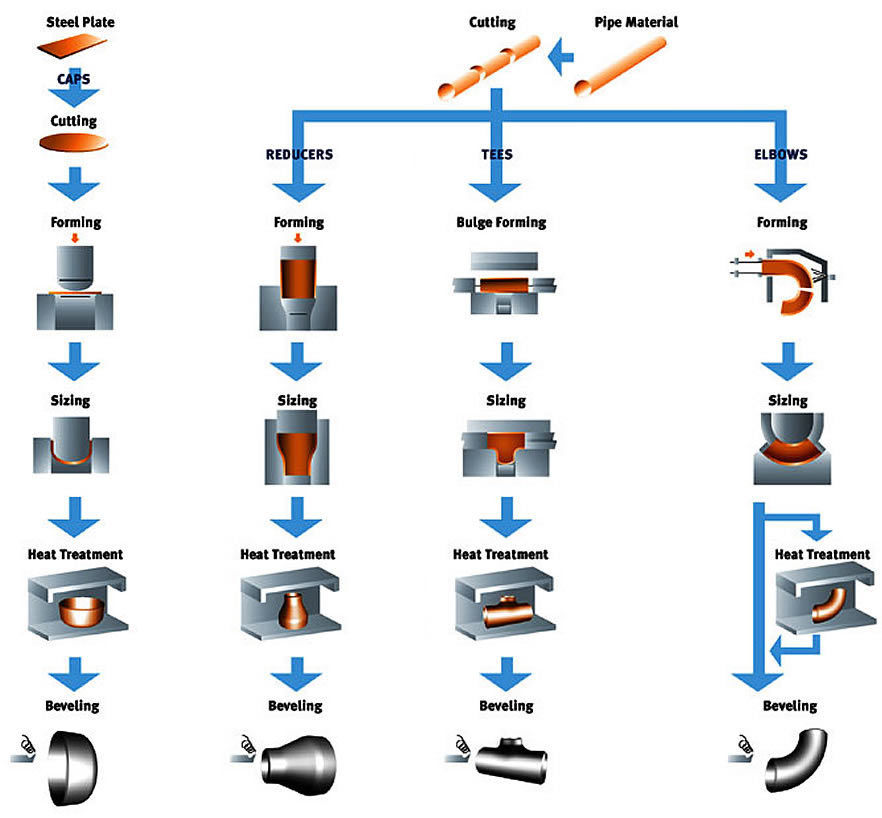

Carbon steel pipe fittings production process

Buttweld Fittings manufacturing process includes a series of steps like Annealing, Straightening, Pickling & Passivation and Polishing.

These fittings are produced using latest technology, ensuring excellent strength and long service life. The process needs a lesser amount of heat treatments to ensure better physical properties.

The series of steps involved in the manufacturing Process of Buttweld Fittings are given in a detailed view below:

Annealing :

Annealing is also known as heat treatment, which plays an active role in the production. In this step, the tubes are carried out in fully automated and conveyor to heat them at certain temperature. Once the tubes get heated, they immediately quench in water.

Straightening :

The tubes are straightened with the help of straightening machine to provide a high degree of straightness in this step.

Pickling :

The process of Pickling refers to the removal of high temperature scale and adjacent low chromium layer of metal from the surface of stainless steel.

Passivation :

Passivation is the process of treating the surface of stainless steels in order to eliminate the contaminants from the metal. The process also helps in promoting the formation of a continuous passive film on a freshly created surface.

Polishing :

The final step, is named as Polishing that reflects the wonderful quality, high aesthetic & hygienic value and high durability of buttweld fittings. Polishing is a essential step to gain excellent features for meeting the varied demands of clients.

How a Butt Weld Fitting is Made?

There are numerous processes for manufacturing butt weld fittings, several examples listed as follows.

Extrusion method (Hot Forming)

The hot-extrusion process consists of enclosing a piece of metal, heated to forging temperature, in a chamber called a "container" having a die at one end with an opening of the shape of the desired finished section, and applying pressure to the metal through the opposite end of the container.

ELBOWS:

Mandrel method (Hot Forming)

One of the most common manufacturing methods for manufacturing Elbows from pipes. After heating the raw material, it is pushed over a die called "mandrel" which allows the pipe to expand and bend simultaneously.

CAPS:

Deep Drawing method

One of the most common manufacturing methods for caps, where plate is cut out in a circle and formed by deep drawing.