An elbow is a pipe fitting installed between two lengths of pipe or tubing to allow a change of direction, usually a 90° or 45° angle, though 22.5° elbows are also made. The ends may be machined for butt welding, threaded (usually female), or socketed, etc. When the two ends differ in size, the fitting is called a reducing elbow or reducer elbow.

An elbow is a pipe fitting installed between two lengths of pipe or tubing to allow a change of direction, usually a 180° or 90° angle, though 45° elbows are also made. The ends may be machined for butt welding (SW) or socketed welding(SW) etc.

Most elbows are available in short radius or long radius variants. When the two ends differ in size, the fitting is called a reducing elbow or reducer elbow.

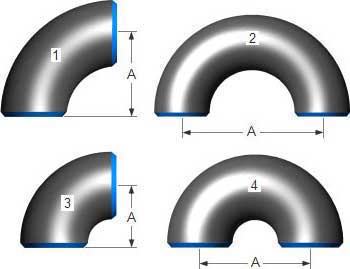

Elbows are categorized based on various design features as below:

-

Long Radius (LR) Elbowis also called LR elbow – means the radius is 1.5 times the pipe diameter

-

L/R 45°Elbow: Long radius 45 degree elbow changes the direction by 45 degrees.

-

L/R 90°Elbow: Long radius 90 degree elbow changes the direction by 90 degrees.

-

L/R 180°Elbow: Long Radius 180 degree return bend allows complete reversal of flow.

-

Short Radius (SR) Elbowis also called SR elbow, – means the radius is 1.0 times the pipe diameter

-

Short radiu 45°Elbow: Short radius 45° elbow changes the direction by 45 degrees.

-

Short radius 90°Elbow: Short Radius 90° elbow is same as LR90 except for the measurement between end of elbow to center line is 1 x NPS.

-

Short radius 180° Elbow: Short Radius 180° return bend allows complete reversal of flow

-

Carbon steel: ASTM/ASME A234 WPB-WPC

-

Alloy steel: --WP 22-WP 5-WP 91-WP 911

-

ASTM A335 P22

-

ASME SA335 P91 elbow

-

ASTM A234 WP 11

-

Low temperature steel: ASTM/ASME A402 WPL 3-WPL 6

-

High performance steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70

-

Stainless steel:

-

ASTM/ASME A403 WP 304-304L-304H-304LN-304N

-

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

-

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H

Elbows are design features as below

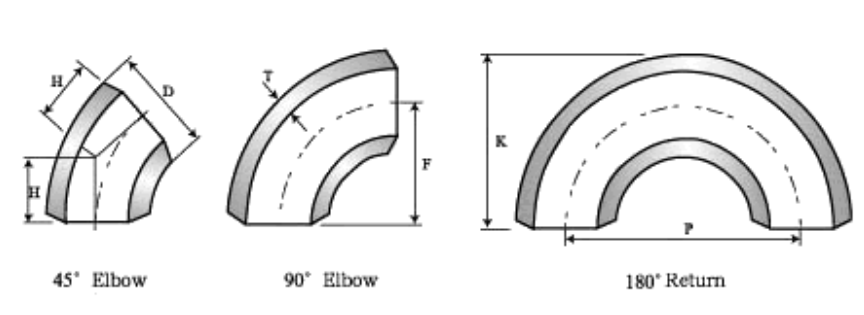

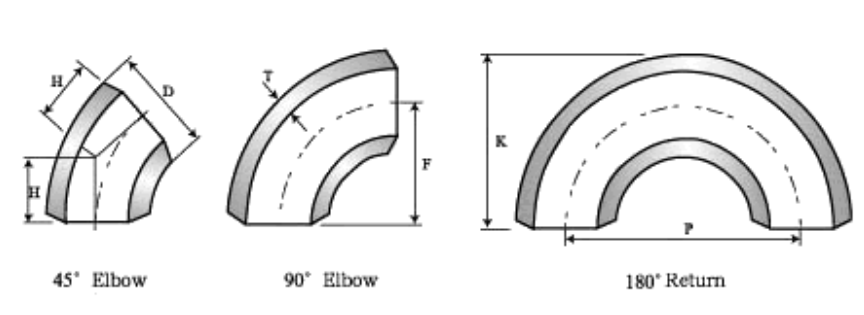

A 90 degree elbow is also called a “90 bend” or “90 ell”. It is a fitting which is bent in such a way to produce 90 degree change in the direction of flow in the pipe. It used to change the direction in piping and is also sometimes called a “quarter bend”.

A 90 degree elbow attaches readily to plastic, copper, cast iron, steel and lead. It can also attach to rubber with stainless steel clamps. It is available in many materials like silicone, rubber compounds, galvanized steel, etc. The main application of an elbow (90 degree) is to connect hoses to valves, water pressure pumps, and deck drains. These elbows can be made from tough nylon material or NPT thread.

A 45 degree elbow is also called a “45 bend” or “45 ell”. It is commonly used in water supply facilities, food industrial pipeline networks, chemical industrial pipeline networks, electronic industrial pipeline networks, air conditioning facility pipeline, agriculture and garden production transporting system, pipeline network for solar energy facility, etc.

Elbows are split into two groups which define the distance over which they change direction; the center line of one end to the opposite face. This is known as the "center to face" distance and is equivalent to the radius through which the elbow is bent.

Here below, for example, you will find the center to face distance of NPS 2 elbows (the A distance on the image)

The center to face distance for a "long" radius elbow, abbreviated LR always is "1½ x Nominal Pipe Size (NPS) (1½D)", while the center to face distance for a "short" radius elbow, abbreviated SR even is to nominal pipe size.

|

Nominal pipe size |

Outside Diameter

at Bevel |

Center to End |

Center to Center |

Back to Faces |

|

45° Elbows |

90°Elbows |

180°Return |

|

H

|

F

|

P

|

K

|

|

DN

|

INCH

|

Series A |

Series B |

LR |

LR |

SR |

LR |

SR

|

LR

|

SR

|

|

15

|

1/2 |

21.3

|

18

|

16

|

38

|

-

|

76

|

-

|

48

|

-

|

|

20

|

3/4 |

26.9

|

25

|

16

|

38

|

-

|

76

|

-

|

51

|

-

|

|

25

|

1 |

33.7

|

32

|

16

|

38

|

25

|

76

|

51

|

56

|

41

|

|

32

|

11/4 |

42.4

|

38

|

20

|

48

|

32

|

95

|

64

|

70

|

52

|

|

40

|

11/2 |

48.3

|

45

|

24

|

57

|

38

|

114

|

76

|

83

|

62

|

|

50

|

2 |

60.3

|

57

|

32

|

76

|

51

|

152

|

102

|

106

|

81

|

|

65

|

21/2 |

76.1(73)

|

76

|

40

|

95

|

64

|

191

|

127

|

132

|

100

|

|

80

|

3 |

88.9

|

89

|

47

|

114

|

76

|

229

|

152

|

159

|

121

|

|

90

|

31/2 |

101.6

|

-

|

55

|

133

|

89

|

267

|

178

|

184

|

140

|

|

100

|

4 |

114.3

|

108

|

63

|

152

|

102

|

305

|

203

|

210

|

159

|

|

125

|

5 |

139.7

|

133

|

79

|

190

|

127

|

381

|

254

|

262

|

197

|

|

150

|

6 |

168.3

|

159

|

95

|

229

|

152

|

457

|

305

|

313

|

237

|

|

200

|

8 |

219.1

|

219

|

126

|

305

|

203

|

610

|

406

|

414

|

313

|

|

250

|

10 |

273.0

|

273

|

158

|

381

|

254

|

762

|

508

|

518

|

391

|

|

300

|

12 |

323.9

|

325

|

189

|

457

|

305

|

914

|

610

|

619

|

467

|

|

350

|

14 |

355.6

|

377

|

221

|

533

|

356

|

1067

|

711

|

711

|

533

|

|

400

|

16 |

406.4

|

426

|

253

|

610

|

406

|

1219

|

813

|

813

|

610

|

|

450

|

18 |

457.2

|

478

|

284

|

686

|

457

|

1372

|

914

|

914

|

686

|

|

500

|

20 |

508.0

|

529

|

316

|

762

|

508

|

1524

|

1016

|

1016

|

762

|

|

550

|

22 |

559

|

-

|

347

|

838

|

559

|

|

|

600

|

24 |

610

|

630

|

379

|

914

|

610

|

|

650

|

26 |

660

|

-

|

410

|

991

|

660

|

|

700

|

28 |

711

|

720

|

442

|

1067

|

711

|

|

750

|

30 |

762

|

-

|

473

|

1143

|

762

|

|

800

|

32 |

813

|

820

|

505

|

1219

|

813

|

|

850

|

34 |

864

|

-

|

537

|

1295

|

864

|

|

900

|

36 |

914

|

920

|

568

|

1372

|

914

|

|

950

|

38 |

965

|

-

|

600

|

1448

|

965

|

|

1000

|

40 |

1016

|

1020

|

631

|

1524

|

1016

|

|

1050

|

42 |

1067

|

-

|

663

|

1600

|

1067

|

|

1100

|

44 |

1118

|

1120

|

694

|

1676

|

1118

|

|

1150

|

46 |

1168

|

-

|

726

|

1753

|

1168

|

|

1200

|

48 |

1220

|

1220

|

758

|

1829

|

1219

|