|

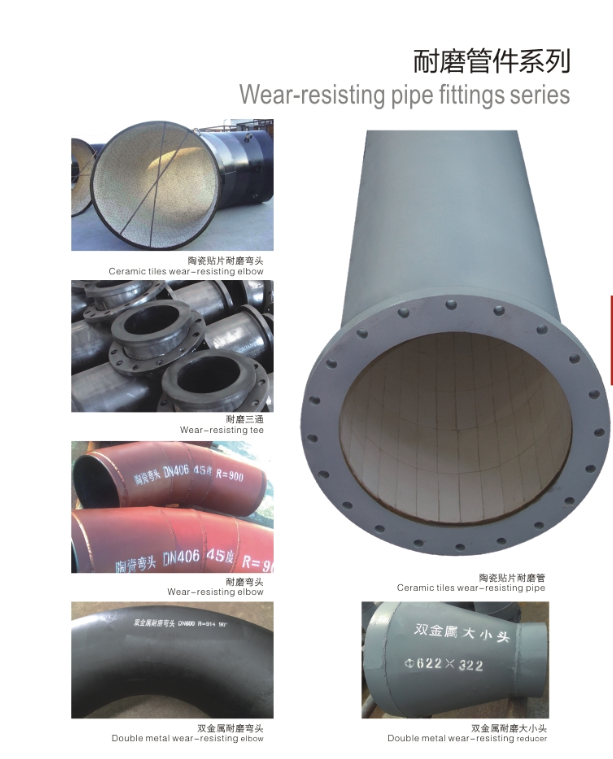

Ceramic Tile Lined Bend Wear-resisting Pipe Fittings |

|

Ceramic tile lined pipe bending, Ceramic tile lined bending have very uniform coating of specially formulated ceramic material that is affixed to the inner of the pipe and gives a very smooth surface. |

|

It is well understood that conveying velocity of ash, its density as well as size of ash particles are major factors that determine wear rate of Bends and Y-Pieces. Here, the use of Alumina Ceramic in Ash Handling systems help in lowering the possibility of wear and damages caused to the internals. Here, our expertise lies in filling the linings in casings manufactured at our works or can also be fitted directly in worn out volute casing at plant site. |

|

Ceramics with very low friction factor at low impingement angles decreases the abrasion of materials maximally. Its low density makes it easy to carry and install. Furthermore, its diamond-like hardness, fine grain structure and superior mechanical strength are the unique features that make it a wide range of demanding applications, such as coal preparation, power generation, iron and steel making, cement, asphalt, dredging, mining and mineral processing, oil and gas drilling. |

|

Metals have good ductility but poor resistance to abrasion - which means that abrasion prevention is required when metal pipes are used in high-temperature fluid catalyst service. On the other hand, ceramics possess great hardness and abrasion resistance, but they are brittle. Metal Ceramic double pipe is a hybrid pipe using metal as an outer pipe and a ceramic material for inner pipe segments, applied together to utilize the two materials' advantages. Hence excellent wear-resistance and good corrosion resistance of the ceramics and high strength and toughness of metal can be well combined to get a comprehensive advantage of wear-resistance, corrosion-resistance and anti-scaling. They are suitable for applications in heavy wear working conditions. |

|

Ceramics are among the hardest materials available and provide ultimate wear resistance in piping. In high wear applications, ceramic lined pipes have been demonstrated to be cost-effective by increasing service life and reducing maintenance costs. Sunny Steel supply ceramic lined abrasion resistant steel pipes to your custom dimensions and budget. Our ceramic linings are the highest quality materials available to ensure that we provide the most cost-effective solutions for our clients. |

|

The Ceramic Tiles could protect Industrial Components against abrasion, impact wear and high temperature of above 1000°C. Standard Flat Tiles of Square & Rectangular Shape having thickness of 6 to 50 mm, with or without central hole are available. |

Suggested Usage of the Ceramic Tile lined pipe reducering:

| Ash Pipe & Elbows | Add-Mix Transport Lines | Coal Piping Clinker Chutes |

| Chutes | Coal Conduit Lining | Coal Handing Chute Lining |

| Fan Lining | Pulverizer Housing Liner | Coal Mill Pulverizer Cone Lining |

| Bumer Feed Pipes | Classifer Cone Lining | Cullet Chutes & Hoppers |

| Cyclone Lining | Downcomer Pipe Lining | Coal Mill Exhauster Lining |

| Fan Housings | Drag Convey or Lining |

Coal Mill Pulverizer Lining |

Hebei Zhongran Pipefitting Co., Ltd.,:http://en.zrpiping.com

- Telphone- 0317-6689999

- E-mail- zhongran@zrpiping.com

- Address- Yanshan County Industrial Park, Cangzhou City, Hebei Province

- Telphone- 0317-6689999

- E-mail- zhongran@zrpiping.com

- Address- Yanshan County Industrial Park, Cangzhou City, Hebei Province

Copyright:Hebei Zhongran Pipefitting Co., Ltd. 冀ICP备19004948号-6